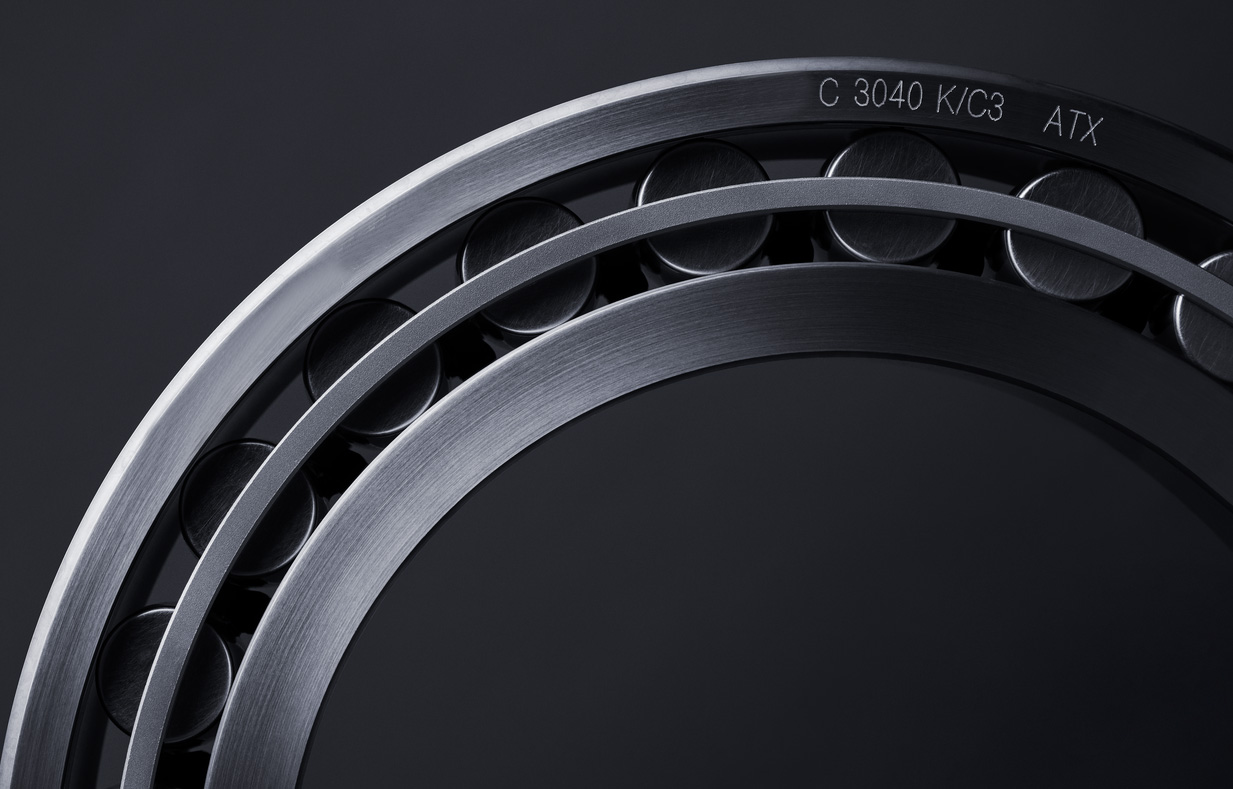

Product

Originating from a professional bearing manufacturer in Germany

Excellent quality, advanced technology, and continuous innovation to provide you with services

Pursuing mutual development with partners, suppliers, and customers, and forming good cooperative relationships

Bearing catalog

Originating from a professional bearing manufacturer in Germany

Excellent quality, advanced technology, and continuous innovation to provide you with services

Pursuing mutual development with partners, suppliers, and customers, and forming good cooperative relationships

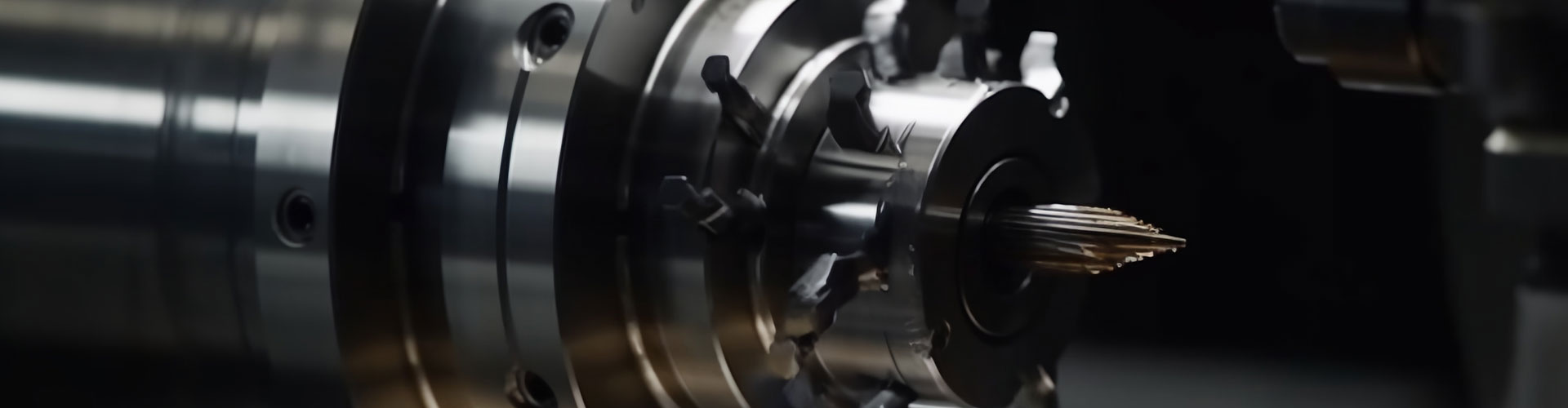

News

Originating from a professional bearing manufacturer in Germany

Excellent quality, advanced technology, and continuous innovation to provide you with services

Pursuing mutual development with partners, suppliers, and customers, and forming good cooperative relationships

About

Originating from a professional bearing manufacturer in Germany

Excellent quality, advanced technology, and continuous innovation to provide you with services

Pursuing mutual development with partners, suppliers, and customers, and forming good cooperative relationships

Search within the website

WeChat QR code

National Service Hotline

15160706956

-

Contacts:Mainland Operations Center

-

Tel:15160706956

-

E-mail:965590702@qq.com

-

Address:Xiamen Lixintong Hardware and Electrical Co., Ltd., Jimei District, Xiamen City, Fujian Province